Views: 0 Author: Site Editor Publish Time: 2025-09-04 Origin: Site

When you plan an investment in a cnc vertical lathe, you want to make sure the cnc machine tool matches your project requirements. You should check the best machine type, cnc machine tool prices, and quality before you decide. The right supplier, like Starfish Machinery, can help you meet your requirements and support your long-term goals. Take a look at this table to see what experts say you should consider:

Factor | Description |

|---|---|

Specific Needs | Know what you want to do with the cnc machine. |

Material Types | Pick a machine that works with your materials. |

Part Dimensions | Make sure the machine fits your parts. |

Required Precision | Choose the quality that matches your needs. |

Production Volume | Think about how many parts you will make. |

Think about what you need to make before buying a CNC vertical lathe. Know what materials you will use and how big your parts are.

Pick a machine that has the right precision for your work. High precision helps your parts fit well and meet quality rules.

Think about how many parts you need to make. The CNC vertical lathe should be able to handle your shop’s work fast.

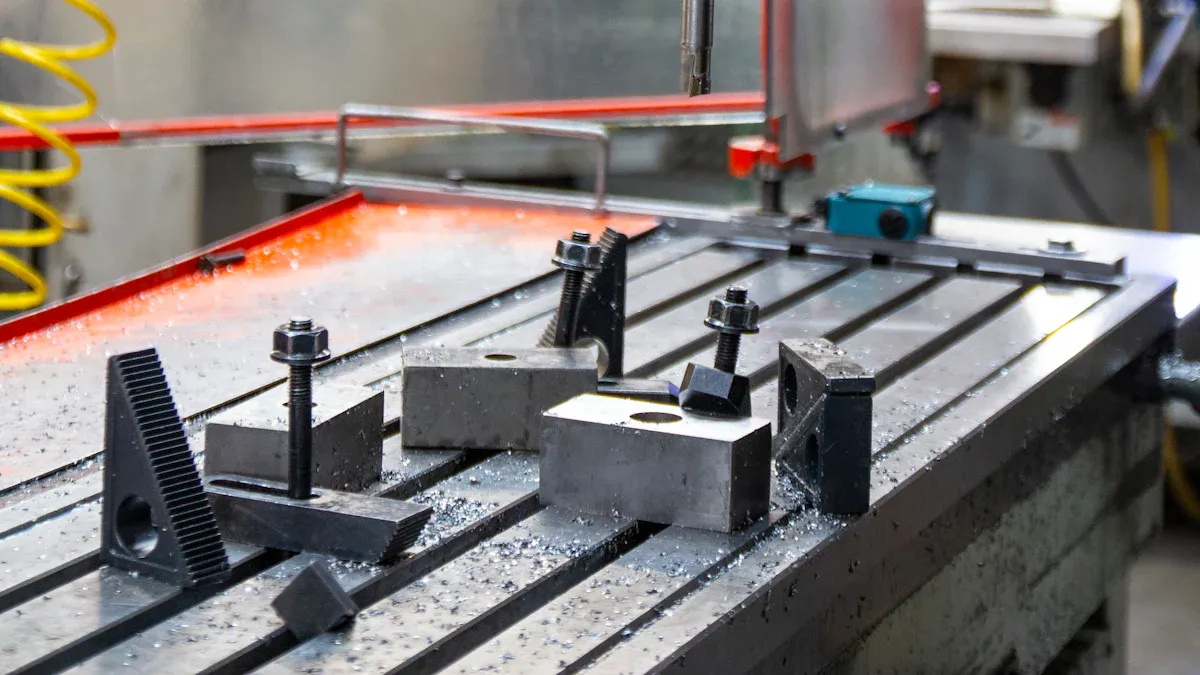

Look at the machine’s details, like table size and spindle power. These things help you work with bigger and harder materials.

Choose a trusted supplier who gives good service and support. Good brands use better materials and help you take care of your machine.

Think about what materials you want to cut with your cnc vertical lathe. Some cnc machines work better with certain metals or plastics. If you want to cut soft metals like aluminum or brass, pick a cnc machine tool that can do that easily. Hard metals like steel or titanium need a machine with more strength and power. Many shops use cnc machine tools for different materials like stainless steel and plastics.

Here’s a quick look at common materials you might work with:

Material Type | Examples |

|---|---|

Soft Metals | Aluminum, Brass, Copper |

Hard Metals | Steel, Titanium, Alloys |

Versatile | Stainless Steel, Aluminum, Brass, Plastics |

When you know your material needs, you can choose the right cnc machine for your work.

Precision is very important in machining. If you need parts with tight tolerances, look for cnc machines that are very accurate. The quality of your finished parts depends on how precise your cnc vertical lathe is. You should check things like spindle runout, how strong the machine is, and the control system. These features help you make sure your parts are the right size.

Tip: Modern cnc vertical lathes can make parts with tolerances as close as ±0.13 mm (±0.005”). This means your parts will fit just right every time.

Some things that affect precision are:

How much the spindle moves when cutting.

How strong and steady the cnc machine tool is.

The control software and how well it runs your programs.

Cooling systems that keep the machine at the right temperature.

If you need high precision, make sure your cnc machine tools have these features.

Do you make simple parts or ones with lots of shapes? If your parts have many curves, holes, or special details, you need a cnc vertical lathe with more options. Some cnc machines have extra axes to help you make tricky designs. You can finish more steps in one setup, which saves time and makes your work better.

Here’s why part complexity matters:

Complex parts need more axes for detailed work.

You need higher precision for tight fits and special shapes.

A cnc machine that can do many steps at once helps you work faster.

If your shop makes complicated parts, look for cnc machine tools with multi-axis features.

How many parts do you want to make? If you have a busy shop or work in big industries, you need a cnc vertical lathe that can keep up. These cnc machines are great for making lots of parts in places like aerospace, automotive, and oil & gas. You can use them for big parts like turbine housings, wheel hubs, or valve bodies.

Here are some industries where cnc vertical lathes are used:

Gear making and mining equipment

Aerospace and defense (engine housings, landing gear)

Automotive and railway (wheel hubs, brake drums)

Oil & gas (valve bodies, pipe flanges)

If you need to make lots of large parts, a cnc vertical lathe is a good choice.

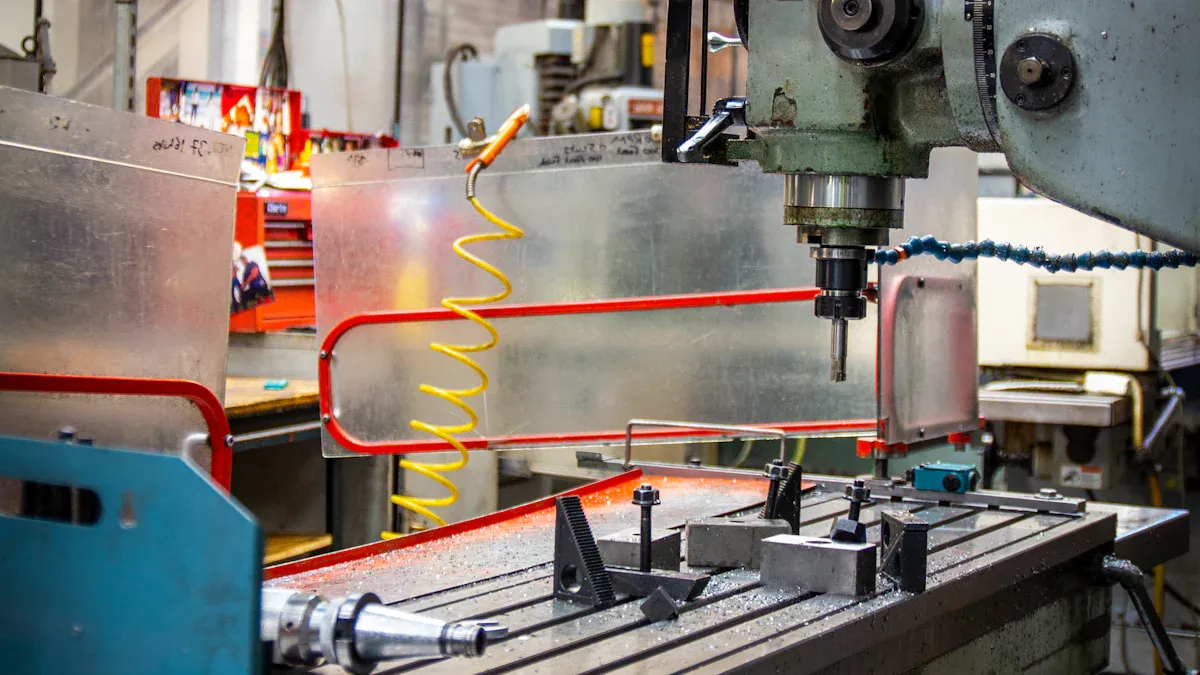

When you check cnc vertical lathes, you want to see what makes each one different. The right features help your shop do better work. Starfish Machinery has cnc machines with a vertical design, multi-axis cnc system, and many models. These things help you work with big and heavy parts and keep the quality high.

Table size is very important to look at first. It shows how big a part you can put on the machine. If you need to work on large wheels, engine housings, or turbine parts, you need a table that is big enough. Here’s a table to help you see what matters:

Specification | Description |

|---|---|

Swing over bed | Biggest diameter you can turn over the bed |

Swing over cross-slide | Biggest diameter that fits over the cross-slide |

Distance between centers | Height from headstock to tailstock |

Horsepower and torque | Power needed for tough cuts |

Rapid traverses | How fast the turret or ram moves |

Accuracy and repeatability | How exact the cnc machine can be |

A bigger table lets you work on larger parts. If you work in aerospace or energy, you need a cnc vertical lathe with a strong table and high weight limit.

Spindle power tells you how strong your cnc machine tool is. More power means you can cut harder stuff and make deeper cuts. If you want to work with steel, titanium, or stone, you need a machine with high spindle power. Here’s a table to show what spindle power works best for different materials:

Spindle Power (KW) | Suitable Materials |

|---|---|

Under 1500 | Wood, Plastic |

1500 – 3000 | Wood, Plastics, Aluminum (2200 and above) |

3000 and above | Hard Metals, Stone (7000 for Stainless) |

If you want to cut tough metals, pick a cnc vertical lathe with strong spindle power. This helps you get better parts and a smoother finish.

Automation makes your work faster and easier. New cnc machines use smart tech to do more jobs with less work. You can set up the machine to load, cut, and unload parts without stopping. Here are some ways automation helps you:

Automation does boring jobs so you can do other things.

It can help your shop make up to 75% more parts without hiring more people.

The machine keeps working, so you get more done and waste less time.

Robots can load, unload, and check parts for you.

Tip: Automation helps you make fewer mistakes and finish jobs faster. You get the same good results every time.

Starfish Machinery’s cnc vertical lathes have smart automation features. You can watch your machine in real time and use AI to help you work better.

The cnc system is like the brain of your cnc machine. Good cnc machines have smart controls that make your job easier. You get automatic tool changers, multi-axis movement, and tight precision. Here’s a table to show the difference between high-end and entry-level models:

Feature | High-End Models | Entry-Level Models |

|---|---|---|

Automation Capabilities | Advanced automation for hard jobs | Not much automation |

Precision | Very precise with tight tolerances | Basic precision |

Control System Types | Advanced CNC systems with auto tool changers | Simple control systems |

Multi-Axis Capabilities | Multi-axis for doing many things at once | Usually just one axis |

Cost | Costs more at first | Costs less at first |

If you want to make tricky parts or need high quality, pick a cnc vertical lathe with advanced cnc system features. Starfish Machinery has models with multi-axis cnc systems, so you can do turning, drilling, and milling all in one setup.

Note: Picking the right features helps your shop do its best work. You save time, make better parts, and can take on bigger jobs with confidence.

When you look at a cnc vertical lathe, the first thing you notice is the price tag. Prices can vary a lot, so it helps to know what to expect. Here’s a quick table to show you the current market range:

Category | Price Range |

|---|---|

Entry-Level CNC Lathes | $5,000 – $20,000 |

Mid-Range CNC Lathes | $20,000 – $80,000 |

High-End Industrial Lathes | $80,000 – $500,000+ |

You might want a basic cnc machine for small jobs, or you may need a high-end model for heavy-duty work. Always match your choice to your shop’s needs and your budget.

Keeping your cnc machine tool in top shape saves you money in the long run. Regular upkeep stops big problems before they start. Here are some things you should know:

You need to change oil, add lubrication, and check calibration often.

Spare parts can get pricey, especially if they are hard to find.

If you call a service technician, the bill can add up fast.

A shop owner once skipped maintenance to save a little money. Later, a spindle broke and the repair cost five times more than regular upkeep.

The cost of a cnc vertical lathe does not stop at the machine itself. You need to buy extra tools and accessories to get the best results. These can include cutting tools, tool holders, coolant systems, and chip conveyors. Some buyers spend almost $10,000 on tooling after buying their cnc machine. These extras help you keep your quality high and your shop running smoothly.

You want your investment to last. Shops in Denmark use cnc vertical lathes for wind energy and medical parts because they trust the precision and quality. When you pick a machine that offers precision, efficiency, and versatility, you keep its value for years. The right cnc machine will help you make great parts and stay ahead in your industry.

When you pick a cnc vertical lathe, trust matters. Brands with good reputations use better materials. They also make smarter designs. Haas, Mazak, and Okuma are well-known brands. These companies have many years of experience. Their customers are happy with their machines. Starfish Machinery is also trusted. It has decades of experience. The company works with big companies. Their machines last long and work well in tough jobs.

Trusted brands use strong materials and smart designs.

Happy customers help build a good reputation over time.

Top brands are known for being tough and precise.

If you want a reliable machine, choose a brand with a good history.

You need good service to keep your cnc machine working. Top suppliers give technical help and training. They also send parts quickly when you need them. Starfish Machinery helps you by email, WhatsApp, video, or phone. If you have a big problem, they send an engineer to your shop. After the warranty ends, you pay fair prices for new parts.

Technical help lets you fix problems fast.

Training and upkeep keep your shop running well.

Quick parts delivery means less waiting time.

Tip: Good service deals save you time and money. You get help fast, so your shop keeps working.

Warranty coverage helps you feel safe about your purchase. Most big brands give one to three years of warranty for cnc vertical lathes. This covers problems with materials and how the machine was made. Okuma and FANUC-controlled machines have two-year warranties. Okuma gives five years for controls. Starfish Machinery gives a 14-month warranty from the debugging date. If a part breaks because of quality, they replace it for free during the warranty. You get help with any problems, and they come to your shop for hard cases.

Note: Warranties do not cover normal use or damage from mistakes. Always check what is covered before you buy.

You want your shop to work well. Plan where you put each machine. Leave space around the cnc vertical lathe. This helps with repairs and cleaning. You need to reach every side of the machine. Keep the machine away from walls and other tools. Heavy machines need a strong concrete floor. Make sure your doors are wide enough for moving machines. If you skip these steps, you could have problems. Your cuts might not be right or your floor could get damaged.

Cnc machines use a lot of electricity. Check if your shop’s power can handle it. Look at the voltage and amps in the manual. You might need new wires or a special circuit. Good power keeps your machine safe. It also stops sudden shut downs.

Operators should feel sure when using the cnc. Easy controls make programming simple and fast. Simple controls mean fewer mistakes and faster jobs. Here’s how good usability helps your team: 1. Automation does not help if operators do not know how to use it. 2. Training helps your team work better and make good parts. 3. Skilled workers can make more parts and earn more money. - Easy controls save time on programming. - Operators feel sure, so there are fewer mistakes and better results.

You want your cnc vertical lathe to last a long time. Many machines let you add upgrades later. Here are some common upgrades:

Upgrade Option | Description |

|---|---|

Efficient Cooling Systems | Stop the machine from getting too hot and keep it working well. |

Predictive Maintenance | Sensors warn you about problems so you can fix them early. |

Durable Components | Strong parts last longer and cost less to fix. |

Easy Access for Maintenance | Makes repairs quick and keeps downtime low. |

Upgrades help your machine work better and stop long breaks.

Safety is always most important in your shop. Follow rules like ANSI B11.6-2022 for safe machine use. Always read the instructions before starting. Make sure the machine is level and all parts are tight. Put safety guards in the right place.

To keep everyone safe, train your team, wear safety gear, and check the machine before each shift. Always hold your workpieces tight and know where the emergency stop is.

If you follow these steps, your shop will be safe and work well.

When you want to buy a cnc vertical lathe, you should make smart choices. Think about what you need to make and how big your parts are. Look at the cnc machine’s features and see if they fit your work. Plan how much money you can spend. Many experts say these steps are important:

Pick a cnc machine that fits your part size and materials.

Make sure the supplier is known for good service.

Think about the price and how long the machine will last.

Here is what top companies found out:

Key Takeaway | Why It Matters |

|---|---|

Technical Specifications | Makes it easy to work with big parts |

Live Tooling | Saves time and helps you be more exact |

Worker Safety | Keeps your team safe with strong machines |

Ask trusted suppliers like Starfish Machinery for help. If you plan well, you can make good choices and skip common problems.

You see CNC vertical lathes in aerospace, rail, energy, and shipbuilding. Shops that work with big, heavy parts love these machines. They help you make things like turbine housings, wheel hubs, and engine parts.

Measure your largest part. Pick a table that fits it with extra space. If you plan to grow, choose a bigger table. You want to avoid running out of room later.

Yes! Many machines let you add features like better cooling, new software, or extra automation. Ask your supplier about upgrade options before you buy.

Most operators learn the basics in a few days. Advanced features may take longer. Good suppliers, like Starfish Machinery, offer training and support to help your team get comfortable fast.

Starfish Machinery gives you technical help, spare parts, and on-site service. You can reach them by phone, email, or video. They want you to keep your machine running smoothly.