Views: 0 Author: Site Editor Publish Time: 2025-09-05 Origin: Site

You want great results when you work on big parts. Floor type milling and boring machines help you do this well. These machines have a flat setup and a strong frame. You can move heavy parts with good accuracy and speed. In the aerospace, heavy equipment, and energy fields, you see these machines a lot. Here is a quick look at where these machines work best:

Industry | Applications |

|---|---|

Aerospace | Making important parts like fuselage sections, turbine housings, and landing gear parts. |

Heavy Equipment Manufacturing | Making big parts for construction and mining machines, like hydraulic cylinders and frames. |

Energy Sector | Making parts like turbine blades and pipeline sections, as renewable energy grows. |

Floor type milling and boring machines help you fix hard problems. Sometimes, parts are too big for normal machines. Sometimes, you need to keep very close measurements or stop heat from changing your part’s shape. A floor type boring and milling machine can handle these problems with smart features and a strong design.

Challenge | Solution |

|---|---|

Workpiece Too Big for the Enclosure | Modular Part Design, Split Components, Full-Assembly Finishing, Machine Modifications, Increased Rigidity, External Supports & Load Sharing |

Failure to Meet Tight Tolerances | Rigorous Setup Validation, Laser Tracking & Alignment, Incremental Finishing Passes, Enhanced Workholding Techniques |

Thermal & Mechanical Distortion | Thermal Management, Low-Heat Roughing, High-Flow Coolants, Mechanical Bracing & Balancing |

You can count on floor type milling and boring machines to do a great job every time.

Floor type milling and boring machines can handle big and heavy workpieces. This makes them great for industries like aerospace and energy.

These machines are very precise. They can reach tolerances as close as ±0.001 inch. This helps make sure projects are accurate and correct.

Strong designs and features like hydrostatic guideways keep the machine steady. They also lower vibrations. This helps make better parts when working on large pieces.

Automation features like quick-change fixtures and robotic handling save time. They help production go faster and make work more efficient.

Real-time monitoring systems watch the machine’s health and accuracy. This lowers downtime and keeps the quality steady in manufacturing.

Big and heavy workpieces need strong machines. Floor type milling and boring machines are set up sideways. This setup helps keep the machine steady. It also stops too much shaking. You get good results, even with long or deep bores.

Here is how these machines help you:

Feature | Description |

|---|---|

Superior Rigidity and Stability | Strong metal parts and a thick design make the machine steady. They also help stop shaking and keep the temperature even. |

Rigid Structure | The machine stays steady and does not shake much. |

Horizontal Orientation | The sideways setup keeps the machine steady. This is important for long and deep bores. |

Hydrostatic guideways help the machine handle heavy workpieces. They also help with the stress from cutting. These guideways lower shaking and stop parts from wearing out. The FTR 3500 model has a welded column and wide ways. This makes it tough and ready for hard jobs.

Tip: Always check safety before you start. Wear safety glasses and gloves. Keep your area clean. Make sure the chip guard works. Follow all safety rules.

You need a big space for large workpieces. Floor type milling and boring machines give you lots of room. You can put big parts on the machine and move them easily. These machines can hold very heavy weights.

Model | Overall Weight (lbs) |

|---|---|

TOS Table Type | 30,860 |

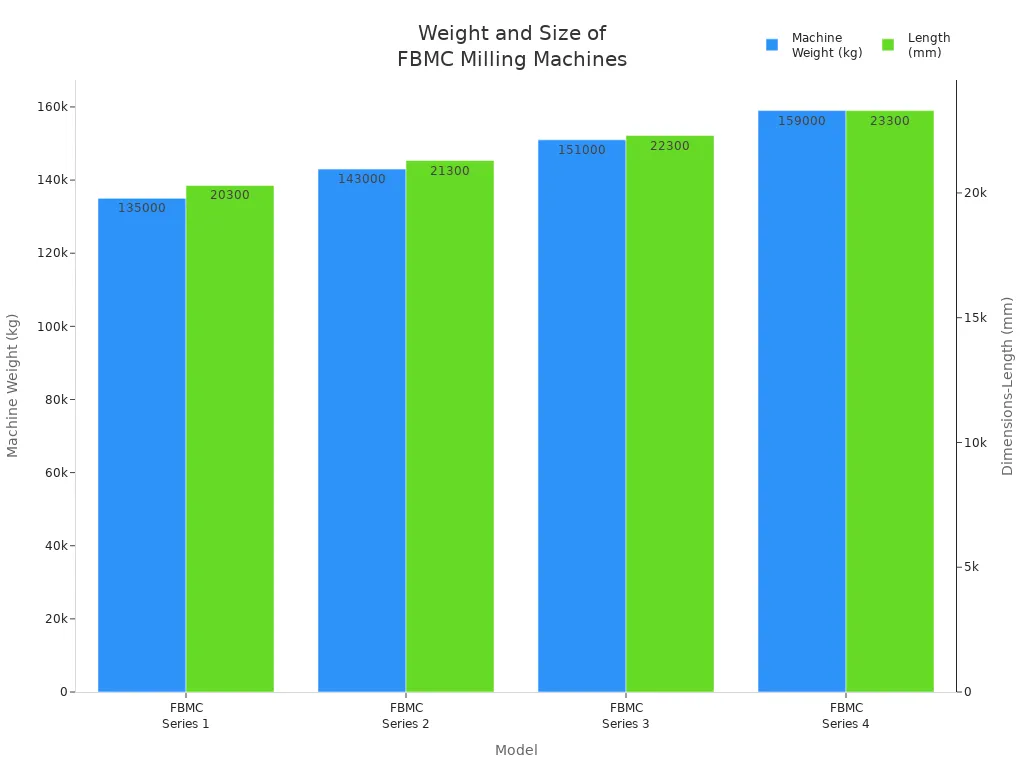

Model | Machine Weight (kg) | Dimensions-Length (mm) |

|---|---|---|

FBMC Series 1 | 135000 | 20300 |

FBMC Series 2 | 143000 | 21300 |

FBMC Series 3 | 151000 | 22300 |

FBMC Series 4 | 159000 | 23300 |

Model | Weight (lbs) |

|---|---|

Johnford FBMC Series | 240,000 – 349,800 |

Model | Max Weight on Table (lbs) |

|---|---|

Daewoo DNB-130R | 20,000 |

You see these machines in places like nuclear power and aerospace. You need to work on big and heavy parts with good accuracy. Floor type milling and boring machines do better than other machines for deep boring and big jobs. You can trust them to handle hard parts and keep your measurements close.

New designs make these machines even better. Some are smaller and fit in tight spaces. Some use sensors to watch the machine while it works. Others use robots to help move big parts. These new ideas help you save time and keep your shop working well.

Note: Always check your machines before you start. Make sure safety devices work. Follow OSHA rules and keep your training fresh.

When you work with big parts, you need to be exact and fast. Floor type milling and boring machines help you do both jobs well. These machines can hold huge parts that are too big for regular tables. You can use them for things like shipbuilding and wind turbine hubs. They also work for other large projects. You get very accurate boring, even on the biggest parts.

Modern boring machines can be very exact. In the best cases, they can be as close as ±0.001 inch. Most shops use a standard of about ±0.005 inch. This is very good, especially for such big and heavy parts. You can trust these machines to give you the same results every time.

These machines have smart features that help them stay precise:

The spindle system has a hollow spindle and a boring spindle with strong bearings. This keeps the spindle steady and accurate.

Hydraulic auto shift for spindle rotation helps save power and gives more torque. You keep accuracy, even when the job is hard.

Constant oil cooling keeps the machine from getting too hot. This stops heat from changing your part’s shape and keeps measurements close.

Ram balancing compensation helps with gravity changes. You get steady accuracy during the whole job.

The CNC system lets you do hard machining jobs easily. You can contour, bore, and mill with high accuracy.

The floor-mounted design keeps the machine steady. You see less shaking, so your work stays precise.

Tip: Always check your machine’s calibration before you start. This helps you make good parts and avoid mistakes.

You can count on these machines for exact work in mass production. They help you meet strict rules for good parts. You can drill, bore, mill, and thread without moving the part. This saves time and keeps your work accurate.

You want your shop to work as fast as possible. Floor type milling and boring machines help by cutting down on time when you are not cutting. Non-cutting time means setting up, changing tools, and moving parts. Cutting this time helps you get more done.

Quick-change fixturing systems let you switch jobs fast. You spend less time getting ready and more time cutting. Automatic tool changers and material movers help too. They move tools and parts quickly, so you do not waste time.

Here is how these machines help you work better:

Feature or System | Impact on Productivity |

|---|---|

Quick-change fixtures | Faster job changes, less waiting |

Automatic tool changers | Fast tool swaps, more cutting time |

Robotic handling | Safe, accurate moves for heavy parts |

CNC and CAD/CAM integration | Smooth teamwork, less setup time |

Real-time data collection | Predicts problems, less surprise downtime |

You can make your whole process automatic. Robots can move big parts safely and put them in the right place. Advanced controls let robots and CNC machines work together. You get smooth production and better speed.

Automatic features like fast feed rates and tool changes keep you working quickly. You can make lots of parts and still keep them high quality. These machines help you make good parts every time.

Note: When you use automation, you work faster and safer. You also make better parts. Always teach your team how to use new systems for the best results.

You can see that floor type milling and boring machines help you be exact and fast. You get good parts, better speed, and you can trust them every time you make something.

Floor type milling and boring machines can do many things. They use more than one axis to move the tool and workpiece. This gives you better control. You can make shapes that are hard to do with simple machines. Some machines use a column or ram for the Z axis. Others use a quill or bar for the W axis. This setup gives you more power. You can reach deep places and still be accurate. It is easy to check where the tool is. This helps you keep your work exact.

Many machines have Tool Center Point Control in 5-axis setups. This helps you work on many sides of a part. You do not have to stop and move the part. This saves time and helps you avoid mistakes. Some machines, like the Johnford FBMC-160, use a moving column for the X axis. They have a rotary table for the V axis. Big ballscrews and strong servo motors help the Y, Z, and W axes move smoothly and accurately.

Multi-axis CNC machining helps you:

Make detailed shapes and smooth curves.

Finish more work in one setup.

Get smoother surfaces.

Do less extra work after machining.

These machines can handle big and tricky parts easily.

You can use these machines in many fields. They work well in aerospace, cars, building, energy, and heavy machines. You can make big airplane parts, car frames, and wind turbine hubs. The machines can do many jobs because they have long X-axis travel. You can work on parts up to 21,000 mm long. The Y axis lets you move up and down for tall parts. The Z axis helps you do deep boring or milling.

Here is how these machines fit your needs:

Feature | Benefit |

|---|---|

Long X-axis travel | Works with very large parts |

Adjustable Y-axis | Handles parts of different heights |

Deep Z-axis stroke | Lets you do deep boring and milling |

Strong machine design | Stays steady during heavy cutting |

Universal heads and tool changers | Switches jobs fast and easy |

You can add universal heads or tool changers to make the machines more flexible. These features help you switch jobs quickly. Your shop can keep running smoothly. You can work with many materials and part sizes. The machines stay steady and accurate, even with tough jobs.

Tip: Try using different accessories to get more from your machines. This helps you finish more jobs and solve new problems.

CNC floor boring machines help you do tough jobs well. These machines use computer numerical control to guide every step. Digital controls help you move the tool exactly where it should go. You can set up the machine for hard jobs and trust it to follow your plan.

Here is a table that shows how digital controls help you:

Feature | Description |

|---|---|

DAS system | Makes automatic changes during boring machining for better accuracy. |

Modular Quill | Lets you change and control boring machining for each job. |

Ram Balance | Keeps the boring machine steady and accurate during heavy-duty boring machining. |

Accura Heads | Gives high accuracy for every boring machining job. |

SSV | Gives advanced control for better boring machining accuracy. |

Adaptive Control | Changes settings right away for top results and accuracy. |

Digital Data System | Watches the boring machine and boring machining process all the time. |

CNC floor boring machines use automation and smart sensors. These features help you finish boring machining faster and make fewer mistakes. You can use robotic tool changers to switch tools quickly. High-speed spindles and advanced tooling systems help you work faster. You get better results with less manual work.

Tip: Always check your digital controls before you start boring machining. This helps you avoid mistakes and keeps your boring machine working well.

You want your CNC floor boring machines to work well every day. Real-time monitoring helps you do this. You use sensors and computer numerical control to watch the boring machine as it works. The system checks important sizes and makes changes right away if needed. This keeps your boring machining accurate and stops bad parts from being made.

Here is a table that shows how real-time monitoring helps you:

Benefit | Description |

|---|---|

Quality Control | Checks part sizes during boring machining to keep quality high. |

Immediate Adjustments | Sensors change boring machining settings to stop mistakes. |

Detailed Reports | Gives you a record of every boring machining job for quality checks. |

Digital Twin Feedback | Collects data to help you adjust boring machining and keep standards high. |

Surface Quality Control | Finds problems fast to keep surfaces smooth and accurate. |

Real-time monitoring helps you keep your boring machine healthy. The system checks the boring machine all the time. If something goes wrong, you get a warning. You can fix problems before they stop your boring machining. This way, you use condition-based maintenance. You do not wait for the boring machine to break. You fix it when the system tells you. This saves time and money.

Real-time monitoring gives you:

Health checks for your boring machine all the time.

Early warnings for boring machining problems.

Less downtime and longer boring machine life.

Better safety and lower costs.

CNC floor boring machines use artificial intelligence and IoT technology. These tools help you know when your boring machine needs care. You get better results and fewer surprises in your shop.

Note: Use real-time monitoring to keep your boring machine working well. You get better boring machining and save money on repairs.

You can see why floor type milling and boring machines are great for big parts. These machines are steady, flexible, and very accurate. Check the table below to learn about their top strengths:

Advantage | Description |

|---|---|

Stability and Rigidity | They stay steady and strong, so you get good results with big parts. |

Versatility | They can do many different machining jobs. |

Precision and Efficiency | They work with high accuracy and speed, even on hard tasks. |

In heavy industries, these machines do jobs that others cannot handle. You get quick work, fewer mistakes, and more choices for every project. Here is how these machines help you make big things:

Feature/Benefit | Description |

|---|---|

They can hold huge parts like engine blocks and machine bases that other machines cannot. | |

Multi-axis Integration | You can bore, face, and shape in one setup, which makes work faster and more exact. |

Reduced Cycle Times | They keep working fast, which is important when you make lots of parts. |

Aggressive Material Removal | Their strong frame lets you cut away lots of material, which is needed for big parts. |

Versatile Machining Operations | You can mill, drill, tap, and finish all at once, so you make fewer mistakes and save time. |

Flexibility in Manufacturing | Big machines can handle tricky shapes and mix lathe and mill jobs. |

You can count on these machines to work well and give you good results. If you need to make big parts, these machines have the strength and options you need.

You can work on parts that are very big and heavy. Some parts can weigh more than 300,000 pounds. They can be as long as 23,000 mm. These machines make it easy to move and work on huge pieces.

You use a strong frame and hydrostatic guideways. CNC controls help you stay exact. These features help you avoid mistakes. You get the right size every time.

Yes, you can work with steel, aluminum, and cast iron. You just change the tool or settings for each material. This lets your shop do many jobs.

These machines are used in aerospace and energy. They are also used in shipbuilding and heavy equipment making. They help make big parts for planes, turbines, and building machines.

You must learn how to use CNC controls and safety systems. You also need to know about automation features. Many shops have classes and manuals. You learn best by practicing with a teacher.