- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-07-29 Origin: Site

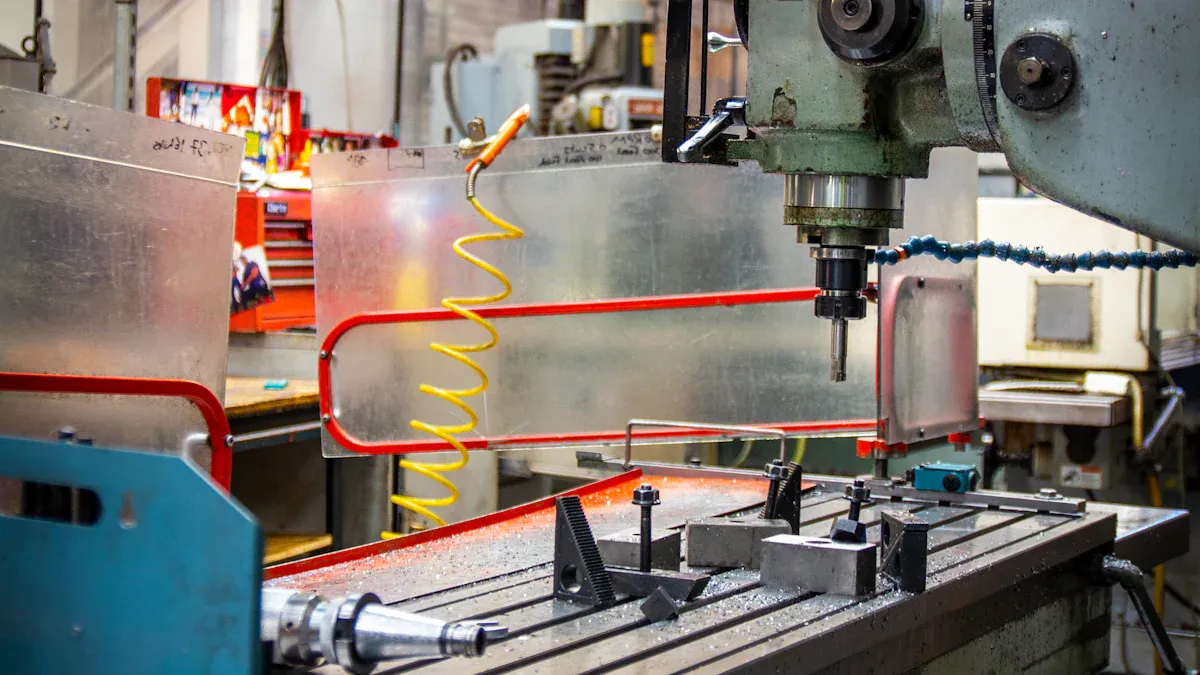

A cnc flat bed lathe uses computer control to do turning, cutting, and drilling. This flat bed cnc lathe has a flat, horizontal bed. The bed helps keep the machine steady and accurate. Operators use its strong frame to work with big or heavy pieces. Flat bed lathes shake less, so they make parts that fit well. These parts are used in cars and airplanes. Some people think only slant bed lathes are precise, but flat bed cnc lathes also work well. Knowing about these machines helps people pick the best lathe for their jobs.

CNC flat bed lathes have a strong, flat base. This base holds big and heavy parts steady. It helps make sure the machine works with great accuracy.

These lathes use computer control to do many jobs. They can turn, cut, drill, and thread parts. They do these tasks with high accuracy every time.

Flat bed lathes are simple to set up and take care of. This makes them good for both new and skilled workers.

They are great for tough jobs in many industries. These include car making, planes, ships, and energy work.

You pick flat bed or slant bed lathes based on your needs. Think about part size, speed, and space. Flat beds are best for big parts. Slant beds are better for fast and exact work.

A flat bed cnc lathe has a bed that is flat and goes side to side. This wide base helps the machine stay steady. The bed is level with the ground, so it can hold big and heavy workpieces. The flat bed is made from one strong piece. It is very stiff and tough. The surface is smooth and hard, which helps it last longer. These features stop the machine from wearing out fast. Operators can move the tailstock and steady rest along the bed. This helps keep long or heavy parts straight while working.

Note: Flat bed lathes are very strong and stable. They are great for tough turning and cutting jobs.

The table below shows how flat bed lathes and slant bed lathes are different:

Feature | Flat Bed Lathe | Slant Bed Lathe |

|---|---|---|

Guide Rails Orientation | Parallel to ground | Inclined at angles (30°, 45°, 60°, 75°) |

Bed Shape | Square | Right triangle |

Cross-sectional Area | Smaller, weaker bending/torsion resistance | Larger, stronger bending/torsion resistance |

Cutting Force Direction | 90° to gravity, prone to vibration | Aligned with gravity, spindle runs smoothly |

Carriage Length (X-axis) | Shorter, fewer tool positions | Longer, more tool positions |

Flat bed cnc lathes are easy to set up by hand. Both new and skilled users can use them without trouble.

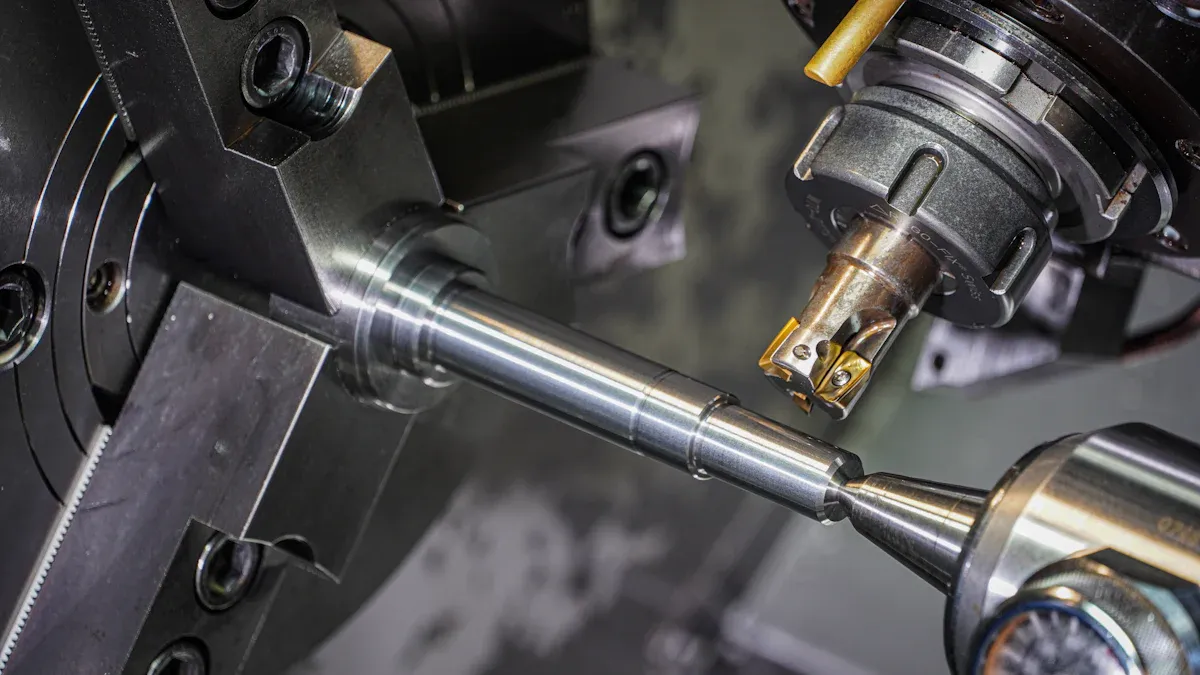

A cnc flat bed lathe has many important parts. Each part does a special job during machining. The table below lists the main parts and what they do:

Component | Function |

|---|---|

Headstock | Runs the motor and turns the spindle. The spindle holds the chuck or collet. |

Collet and Chuck | Hold the workpiece tight. The chuck fits on the spindle for different sizes. Collets hold small parts. |

Tailstock | Holds up long workpieces at the other end of the bed. Uses hydraulic force to help. |

Lathe Bed | Is the base of the machine. It holds all the other parts. The carriage moves on the bed. |

Carriage | Holds the cutting tools. It slides on the bed to cut the workpiece. |

The cnc system controls all these parts. It lets you program how the spindle and tools move. The system has a screen and pictures to help users. Operators can save many jobs in the control system. Oil is added automatically to keep the spindle, gears, and rails working well. This stops parts from wearing out and keeps the machine accurate.

Flat bed cnc lathes can work with big and heavy pieces easily. The strong bed and wide rails make the machine very solid. This helps with tough jobs like turning long shafts or big parts. The machines use strong iron beds and hard rails. These parts do not wear out quickly and keep the machine working well.

Flat bed lathes can handle workpieces up to 2 tons and 12,000 mm long. For example, the CK6163E Heavy Duty model can turn parts up to 630 mm wide and 12,000 mm long. These machines are used for big machines, oil and gas pipes, and train parts.

Flat bed cnc lathes use special guideways that resist wear.

The contact surfaces use special materials to keep them accurate.

The machines can turn inside and outside surfaces, cones, and threads.

Operators think these lathes are easy to use and fix.

Flat bed cnc lathes are a good choice for general and heavy-duty jobs. Their simple design and strong support make them popular for working with large, heavy parts.

Operators start by getting the digital design ready. They also set up the machine. They use special software to make and manage part designs. The most common software types are CAD, CAM, and simulation tools. CAD helps draw parts. CAM makes tool paths. Simulation tools check the process. The table below shows the main software types and examples:

Software Category | Description | Examples |

|---|---|---|

CAD Software | Design creation | AutoCAD, SolidWorks, Fusion 360 |

CAM Software | Converts designs to CNC code | Mastercam, GibbsCAM, Fusion 360 |

G-code Editors | Edit CNC programming code | NC Corrector, G-Wizard Editor |

CNC Simulation Tools | Visualize and simulate machining | VERICUT, NC Viewer |

Toolpath Optimization | Optimize cutting paths | Built into most CAM packages |

DNC Software | Machine communication | Predator DNC, CIMCO DNC |

Monitoring Systems | Track machine performance | MDC-Max, FactoryWiz |

Post-Processing Tools | Convert CAM output to machine-specific code | Usually part of CAM packages |

Integrated CAD/CAM Suites | Combine CAD and CAM functions | Fusion 360, BobCAD-CAM |

3D Modeling Software | Create complex or artistic models | Rhino, Blender |

Quality Control Software | Ensure accuracy of machined parts | PC-DMIS, Quality Control Systems |

Custom CNC Control Software | Specialized machine control | LinuxCNC, Mach3/Mach4 |

After designing the part, the operator puts the program into the CNC controller. They lock the workpiece in the lathe chuck. They put the needed cutting tools in place. The operator checks the machine’s reference points. They make sure coolant and oil systems are ready. This careful setup helps stop mistakes during machining.

The CNC flat bed lathe follows a clear order from setup to finished part. Each step helps the process go well and stay safe. Here is a usual order:

Turn on the CNC machine and set up the axes.

Set the home positions for good reference.

Lock the workpiece in the chuck and check it.

Put and adjust the cutting tools in the turret.

Load the G-code program into the controller.

Run a test or dry run to find mistakes.

Start the machining cycle and watch tool moves.

Use coolant and check the oil system.

Check the part size with probes or calipers.

Take out the finished part and clean the machine.

During machining, the lathe does many main jobs. The table below lists the most common steps:

Machining Step | Description |

|---|---|

Straight Turning | Reduces the diameter evenly; removes large amounts of material. |

Facing | Creates a flat surface at the end of the workpiece. |

Drilling | Makes holes in the workpiece. |

Boring | Enlarges existing holes for better fit or finish. |

Taper Turning | Produces a part with a gradually changing diameter. |

Grooving | Cuts narrow grooves for rings or seals. |

Parting | Separates the finished part from the raw stock. |

Knurling | Adds a textured pattern for better grip. |

Threading | Cuts screw threads on the inside or outside of the part. |

Operators watch the CNC system during the process. They make changes if needed to keep quality and safety.

CNC flat bed lathes are very precise and repeat parts well. They use computer control and strong machine parts. The CNC system follows the program exactly. This makes each part match the design. The machine uses linear scales for accurate feedback. Regular checks and a steady room help keep the lathe accurate. The headstock and bed are made to stop heat changes and shaking. This helps the machine cut better.

Tip: Checking tool wear often and changing tools on time keeps machining quality high.

Safety is very important in CNC work. Modern flat bed lathes have emergency stop buttons. They also have doors that lock and sensors for overloads. Operators must wear safety shoes and goggles when setting up tools. Only trained people should use the machine. They should know where the emergency stops are and check them often. Operators must stop the machine if they see any problems. Big workpieces may need more than one person and special lifting tools for safety.

Operators should never touch the workpiece or spindle while running.

Do not put tools or things on the slide or door.

Power must be off before repairs or maintenance.

Good lighting and a clean area help stop accidents.

CNC flat bed lathes follow strict safety rules like CE and ISO. Regular training and practice drills help operators work safely and well.

Flat bed lathes do many jobs in factories. They shape metal and plastic parts very well. Operators use them for turning, facing, and threading. These lathes also do boring, drilling, and grooving. Many shops use flat bed lathes to make engine parts and shafts. They also make custom parts for machines. The strong bed holds heavy pieces steady while cutting. This helps each cut stay smooth and neat.

Some common jobs are:

Turning big shafts for ships or trains

Cutting threads on pipes for oil and gas

Machining engine blocks for cars and trucks

Making exact molds for plastic products

Creating custom parts for special machines

Note: Flat bed lathes can make simple or tricky shapes. They are good for single parts and small batches.

Flat bed lathes help many industries that need strong, accurate parts. These machines are important where size and weight matter a lot. The table below shows how different industries use flat bed lathes:

Industry | Applications and Characteristics |

|---|---|

Automotive | Engine parts, transmission parts, drive shafts |

Aerospace | Aircraft parts, landing gear, turbine blades |

Medical | Surgical tools, implants, precision instruments |

Shipbuilding | Propellers, long shafts, heavy-duty parts |

Energy | Turbine parts, generator rotors, power plant parts |

Defense | Military vehicles, artillery, gun barrels |

General Engineering | Machinery parts, custom prototypes |

Mold Manufacturing | Precision molds for plastic and metal products |

Flat bed lathes help companies meet tough quality rules. The machines use cnc control for repeatable results. Many factories pick flat bed lathes for heavy-duty work. These lathes are good for big projects and custom jobs.

Flat bed cnc lathes and slant bed cnc lathes look different. The flat bed cnc lathe has a bed that is flat and goes straight across. Two rails run side by side, level with the ground. This makes the machine look like a rectangle. It gives a strong base for heavy parts. The slant bed cnc lathe has rails set at an angle, from 30° to 75°. This makes the bed look like a triangle. The slant bed is thicker and stronger. It helps the machine stay stiff and lines up cutting forces with gravity.

Aspect | Flat Bed CNC Lathe Characteristics | Slant Bed CNC Lathe Characteristics |

|---|---|---|

Bed Structure | Horizontal, rectangular bed | Inclined, triangular bed |

Rigidity | Lower resistance to bending and torsion | Higher rigidity, better resistance to bending and torsion |

Guide Rails | Single row linear guides | Double row linear guides |

Chip Removal | Harder to automate | Often has automatic chip conveyor |

Footprint | Larger, needs more floor space | Compact, fits smaller workshops |

The slant bed cnc lathe moves chips away better and takes up less space. The flat bed cnc lathe is steady and holds big parts well.

Cnc lathes work differently because of their bed shape. The slant bed cnc lathe is more accurate and faster. Its slanted bed shakes less and moves chips out easily. This gives smoother parts and saves time. The flat bed cnc lathe is best for big, heavy parts. It holds them steady but may not remove chips as fast. It also runs at lower speeds.

Aspect | Slant Bed CNC Lathe | Flat Bed CNC Lathe |

|---|---|---|

Accuracy | High, less vibration, better surface finish | Stable, but surface finish may not match slant bed |

Speed | Fast, supports high feed rates and spindle speeds | Slower, less efficient for high-speed operations |

Chip Removal | Smooth, reduces tool wear | Slower, can cause more frequent tool changes |

Workpiece Suitability | Best for small, complex, precise parts | Best for large, heavy workpieces |

Cost & Maintenance | Higher cost, more complex maintenance | Lower cost, easier to maintain |

Tip: Slant bed cnc lathes are good for fast, exact jobs. Flat bed cnc lathes are better for big, tough work.

Picking a flat bed or slant bed cnc lathe depends on your needs. Think about the size of your parts, how fast you want to work, and how much space you have. Flat bed cnc lathes are great for heavy jobs and big parts. They are easy to fix and last a long time. Slant bed cnc lathes are good for making lots of small, exact parts. They save space and can use robots.

Flat bed cnc lathes are steady for long, heavy parts.

Slant bed cnc lathes move chips out fast and are comfy to use.

Slant bed cnc lathes cost more but work faster in busy shops.

Flat bed cnc lathes cost less and are strong for hard jobs.

Shop owners should check their space, if they need robots, and how skilled their workers are.

Note: Big parts usually need a flat bed cnc lathe. Small, exact parts are better with a slant bed cnc lathe.

CNC flat bed lathes give strong support for heavy-duty and precise machining. They work well with large parts and offer easy maintenance. When choosing a lathe, users should match the machine to the size and type of work. The table below shows key points for picking the right lathe:

Step | What to Check |

|---|---|

1. Set a budget | Match price to business needs |

2. Check size | Make sure the lathe fits the parts |

3. Compare brands | Look for good support and warranty |

Matching lathe features to industry needs helps factories work faster and smarter.

A CNC flat bed lathe can cut steel, aluminum, and brass. It also works with plastics and some composites. The strong bed holds heavy and hard materials. Operators pick the right tools for each job.

The CNC system controls all movements. The machine follows the program step by step. Linear scales and sensors help each cut stay exact. Checking and changing tools often keeps the cuts accurate.

Operators think these lathes are easy to care for. The design lets you reach parts quickly. Automatic oiling keeps moving parts working well. Cleaning and checking the machine often helps it last longer.

Yes, beginners can use this machine. The control panel has easy screens and buttons. Many models have safety features and guides. Training helps new users learn to use the machine safely.

Most machines have emergency stop buttons, locked doors, and overload sensors. These features keep operators safe while working. Safety rules say users must wear goggles and safety shoes.

content is empty!