- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-07-31 Origin: Site

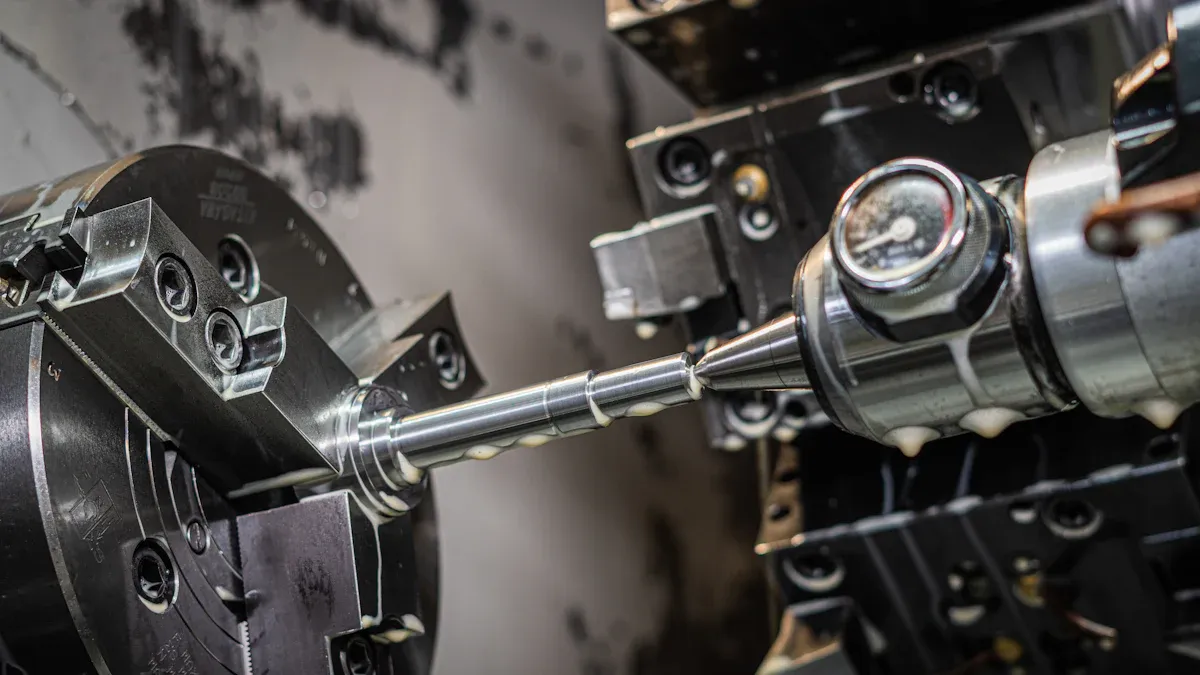

Choosing the right CNC flat bed lathe starts with knowing what you need. You should match the lathe’s features to your work goals and workpiece size. Many shops lose money by not doing this first step. For example, some forget about things like material type, how much they need to make, or how their space is set up. Others miss key details like swing over bed or spindle speed. Before picking a CNC, think about what you make now and what you might make later. This helps you save money and keeps your workshop running well.

Make sure the lathe’s size and features fit your workpiece size. Think about the material and how much you need to make. This helps you save money and work better.

Pick a lathe that matches your workers’ skill level. Simple controls help new workers learn faster. They also help everyone stay safe.

Find a strong and steady machine. It should have good accuracy and parts you can trust. This gives you better surface quality and less machine downtime.

Look at different brands closely. Check how well they are made. See if they offer good support and have spare parts. This keeps your investment safe.

Use this guide as a checklist. Pick a lathe that fits your needs now. Make sure it fits your workshop space. It should also let you upgrade in the future.

First, think about what kind of workpiece you want to make. The size and material of your workpiece will help you pick the right CNC flat bed lathe. Most small or medium workshops use lathes for pieces with a swing from 9 to 16 inches. Bed lengths are usually between 30 and 60 inches. Some jobs need bigger machines. These can turn pieces up to 51 inches wide and 201 inches long. The material you use is also important. You might work with carbon steel, alloy steel, stainless steel, aluminum, copper, plastics, or wood. Each material needs special care. For example, stainless steel needs more spindle power and a strong machine. Plastics and wood need gentle handling so they do not break. The best lathe for you fits both your workpiece size and the material you use.

Tip: Always look at the biggest swing and bed length before you buy a CNC lathe. This helps you work on all your projects now and later.

Parameter | Range / Description |

|---|---|

Turning Diameter | 26 to 51 inches |

Maximum Workpiece Length | 63 to 201 inches |

Typical Materials | Carbon steel, alloy steel, stainless steel, aluminum, copper, plastics, wood |

Typical Use Cases | Heavy-duty turning, threading, boring, drilling, facing |

Workshop Scale | Small to medium-sized workshops, suitable for long and/or large workpieces |

Now, think about how many parts you want to make. If you make lots of parts, you need a CNC lathe that works fast and does not break down. If you only make a few parts or custom jobs, you need a machine that is easy to change for new jobs. The kind of workpiece and material you use will also change how you work. Big jobs, like making airplane or oil parts, need a strong lathe with special features. Always pick a machine that matches how much you want to make.

High production: Pick speed, automation, and long tool life.

Low production: Choose easy setup and flexibility for new jobs.

How much your workers know is very important for safety and good work. Skilled workers can read drawings, write CNC programs, and pick the right tools. They know how fast to cut each workpiece and material. This helps them work faster and make fewer mistakes. Good workers also follow safety rules, like clamping parts tight and cleaning up chips. This keeps people and the lathe safe. If your workers are new, get a CNC lathe that is easy to use and has clear safety features.

Note: Training your workers makes your shop safer and helps them do better work. It also gets your shop ready for harder jobs in the future.

When you pick a flat bed cnc lathe, you need to think about some important things. The first thing is how stable the machine is. A strong base and good guide rails help you get better accuracy and smoother surfaces. If the guide rail moves or wears out, your work will not look as good. You should pick a cnc flat bed lathe with a tough bed and a design that stops shaking. Some new lathes have an L-shaped or slanted bed. This helps the machine handle shocks and heat better. It keeps your work accurate, even if you use the lathe for a long time.

Accuracy is also very important. You want a lathe that can go back to the same spot every time. This is needed when you make parts that must fit just right. Good tools and strong holders help stop shaking and make the surface look better. You should also think about your workshop. If the temperature and humidity stay the same, your lathe will work better. If these change a lot, the lathe can get bigger or smaller, and this can mess up your work.

Here is a table to help you compare important performance factors:

Performance Factor | Description |

|---|---|

Processing Requirements | Match part type, precision, material, and batch size to the lathe configuration. |

Bed Material | Cast iron offers high rigidity. Steel plate provides thermal stability. Composite beds balance both. |

Servo System | High precision and stability ensure accurate position control and less downtime. |

Spindle and Turret | Precision, rigidity, speed, and torque affect machining quality and efficiency. |

Cooling and Chip Removal | Good cooling keeps temperature stable. Fast chip removal prevents processing issues. |

Machine Tool Accuracy | Repeat positioning accuracy and stability ensure consistent precision. |

Machine Tool Rigidity | Stable under cutting forces and vibration for better surface quality. |

Machine Tool Reliability | Reliable machines reduce downtime and maintenance costs. |

Convenience of Operation | User-friendly controls and automation reduce errors. |

After-sales Service | Fast support extends equipment life and keeps your shop running. |

Tip: You should check your lathe often, use sharp tools, and have skilled workers. This helps you work faster and get better results.

A flat bed cnc lathe has many features that make it a good choice for lots of shops. The flat, square bed gives the machine strength and makes it easy to take care of. Some models, like ones with a "W" in the name, have wider rails. This makes the machine more stable and helps you get better accuracy. Some brands use hard steel rails that you can change. These last longer and are easy to swap, which saves you time and money.

A good flat bed CNC lathe is also built to be robust. High-quality machines feature heavy-duty beds and durable turrets, allowing you to handle large parts and demanding tasks. With improvements in turret speed and bed design, these machines now enable faster tool changes and more efficient work.When you look at flat bed and slant bed lathes, you should know how they are different:

Flat bed cnc lathes have a flat bed. This makes them strong and simple, but the way they cut can cause more shaking.

Slant bed lathes have a slanted bed. This helps the machine shake less and makes the spindle work better.

Flat bed lathes are best for big, heavy, and simple parts. They cost less and are easy to fix.

Slant bed lathes can hold more tools and are better for jobs that need more steps. They are great for hard, detailed work in places like car or plane factories.

Here is a quick comparison:

Feature | Flat Bed CNC Lathe | Slant Bed CNC Lathe |

|---|---|---|

Bed Orientation | Horizontal, stable, simple | Inclined, rigid, better chip removal |

Rigidity & Vibration | More vibration, perpendicular cutting forces | Less vibration, forces aligned with gravity |

Tool Positions | Fewer, simpler | More, supports automation |

Application Suitability | Heavy, large, basic parts | High-precision, complex, automated tasks |

Maintenance | Easy, simple structure | Durable, higher initial cost |

Machining Accuracy | Good for basic turning | Higher precision, repeatability |

Note: Pick a flat bed cnc lathe if you need a machine for simple turning, big parts, or for learning. Choose a slant bed lathe if you need to do hard, detailed, or automatic work.

The control system is like the brain of your cnc flat bed lathe. It decides how easy the machine is to use and how fast your workers can learn. Brands like GSK, Siemens, and Fanuc make good and smart control systems. You should pick a control system that fits what your team knows and what you need to make.

New cnc controls are easier to use now. Some, like the HEIDENHAIN TNC7, let you change the home screen and watch videos of your work. These things help new workers learn faster. Some controls let you draw shapes right on the screen. This makes setup quicker and helps you make fewer mistakes. Touchscreens, 3D pictures, and real-time checks help you avoid errors and work better.

If you want to work faster, pick a flat bed cnc lathe with a control system that lets you use more than one finger and add 3D models. These things make programming easier and mean you do not need other software. You can also change the machine settings for each job. This helps you get the best results every time.

Tip: A control system that is easy to use helps your team learn faster and work better.

Before choosing a flat bed CNC lathe for your shop, it's essential to compare different brands and models. Start by evaluating the build quality of the machine. High-quality lathes are constructed with durable parts and utilize specialized methods for creating the frame. For example, some manufacturers follow strict quality standards, such as ISO 9001, and use high-grade castings that enhance the machine's strength and longevity. It is also beneficial if the manufacturer employs Finite Element Analysis (FEA) to test the machine's structural integrity. This testing helps to prevent issues like vibration or premature wear.

Another crucial factor is the availability of spare parts. Some manufacturers maintain a significant inventory of machines and parts, with trained staff and dealers to provide quick assistance if something breaks down. When selecting a brand, prioritize those with a strong reputation and a reliable support system.

After-sales support is crucial for the success of your shop. You need a company that offers a solid warranty and technical assistance. Some manufacturers provide regular maintenance checks and 24/7 customer service, while others conduct proactive check-ups to prevent issues before they arise. Some companies even offer on-site repairs and provide training to your workers on how to operate the machine. These services ensure that your lathe operates smoothly and minimize downtime.

Picking a flat bed cnc lathe means you need to think about a few things. Use this cnc lathe selection guide to help you choose the right one:

Know your production needs. Think about how many parts you will make, how hard they are, and what materials you use. Make sure the lathe can do your jobs now and later.

Check the machine size and your space. Measure your shop and see if the lathe will fit. You need room to use and fix the machine.

Look at key specs. Check spindle speed, horsepower, and how many tools it can hold. These things change how fast and easy you can work.

Check control systems. Pick a lathe with controls that are easy to use and work with your CAD/CAM software. This makes setup and programming simple.

Compare brands and their reputation. Choose a company known for good machines and support. Good brands give you better value over time.

Think about machine weight and power use. Heavier lathes are more stable and make fewer mistakes on big jobs. Power costs are usually low, but they add up if you run the machine a lot. For example, a 40 kW machine may cost about $2 per hour to run, which matters for long jobs.

See if you can upgrade the machine. Newer lathes often let you add new parts or features later. This helps your machine last longer and saves money on repairs.

Remember after-sales support and training. Good help and training keep your lathe working well and stop long breaks.

A good flat bed cnc lathe should fit your needs, fit your shop, and let you add upgrades. Always think about both the first price and the help you get later.

A flat bed cnc lathe that is cared for can last 10 to 20 years or more. Cleaning, checking, and changing parts help it last longer. New machines with sensors and smart software can last even longer if you keep them in a good place.

Tip: Use this cnc lathe selection guide as a checklist. It helps you pick a flat bed cnc lathe that helps your shop grow and gives you good parts for many years.

Picking the right lathe for your shop means it must fit your needs. If you do research first, you can skip problems like setup trouble, bad finishes, or missing parts. When your lathe matches your goals, your business can grow and work stays smooth. In 2025, most shops want lathes with strong beds, good support, and ways to upgrade later. Use this guide as a checklist so you can make smart choices every time you buy a lathe.

You will notice that a flat bed lathe has a horizontal bed, which gives it strength and stability. A slant bed design helps with chip removal and supports more complex machining tasks.

You should check your cnc machine daily for cleanliness and lubrication. Schedule a full inspection every six months. Regular care helps prevent breakdowns and keeps your equipment running smoothly.

Yes, a beginner can operate a cnc flat bed lathe. Many modern machines have user-friendly controls and safety features. Training and practice help you build confidence and skill.

You can process metals like steel, aluminum, and copper. You can also work with plastics and wood. Always select the right tools and settings for each material to get the best results.