- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-07-30 Origin: Site

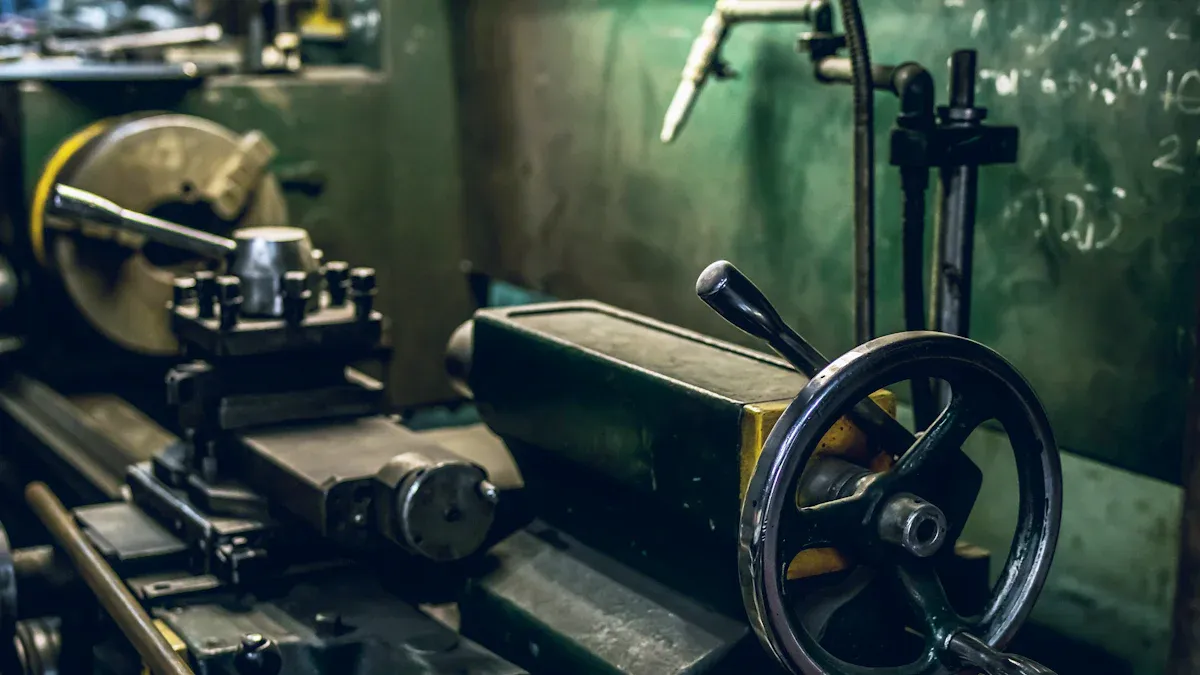

Factories need accurate cnc systems and strong lathe designs. These help them make more products and have fewer mistakes. They also allow for flexible and automatic work. New control systems and real-time error fixes help a lot. The flat bed cnc lathe is now very important in modern factories.

CNC flat bed lathes are strong and precise machines. They help factories make big, heavy parts. These machines make fewer mistakes and work faster.

Important features include powerful spindles and fast tool changers. Smooth guideways and smart control systems help the machine work better. These features also make it easier to use.

Picking the right lathe means matching its size and power to your needs. You should think about your parts, materials, and how much you want to make. This helps you get the best results.

Planning space, workflow, and maintenance is important. This helps the lathe work well and saves money over time.

Factories pick a flat bed cnc lathe for many reasons. These machines are strong and can handle tough jobs. Operators can move big and heavy parts easily. The simple design makes it easy to fix or clean. Many factories save money by using these machines for many jobs. They are good for making long shafts and big parts. They also help build heavy machine pieces. Power transmission, oil and gas, railway, and marine engineering use these machines a lot.

A cnc flat bed lathe makes very accurate parts. It can make the same part over and over again. This helps factories make better products with fewer mistakes. The machine can work by itself most of the time. This means it can make things faster and stop less often. High spindle speeds help finish work quickly. Factories save money because the machine works fast and needs fewer workers. Better quality control means fewer bad parts are made.

Manufacturers want certain features in a flat bed cnc lathe. These features help the machine work its best. The table below shows the most important parts and what they do:

Component | Function and Critical Features |

|---|---|

Spindle | Holds and spins the workpiece; works fast and smooth; uses bearings and oil for easy turning. |

Turret | Changes tools quickly; holds many tools; helps with hard jobs. |

Guideways | Help parts move straight and smooth; last a long time; keep movement steady. |

Servo Motors | Move machine parts; work fast and are very exact; give feedback right away. |

Control System | Reads instructions; controls motors and hydraulics; can do many jobs at once. |

Cooling System | Keeps spindle and motors cool; uses water or air; works quietly and well. |

Lubrication System | Sends oil to parts; often works by itself; keeps machine running smoothly and easy to care for. |

A modern cnc flat bed lathe has a strong cast-iron bed with ribs. The spindle motor is powerful and keeps spinning even with heavy loads. Automatic tool changers and chip removers help the machine work without stopping. Advanced controllers let workers check the machine from far away. These features make the flat bed cnc lathe very important in many factories.

Factories want flat bed cnc lathes that are strong. Machines with an HT300 cast iron base are tough and stop shaking. This makes the lathe last longer and helps it work well during hard jobs. Guideways with special coatings help parts move smoothly and stop rubbing. The spindle has strong bearings, so it works well with heavy loads. Automatic oil systems and chip movers make it easy to care for the machine.

Build Quality Aspect | Influence on Longevity and Maintenance |

|---|---|

HT300 Cast Iron Base Casting | Makes the machine strong and stops shaking |

Induction-Hardened Guideways | Helps parts move easily and last longer |

Precision Spindle Assembly | Handles heavy work and needs less fixing |

Automatic Lubrication & Chip Conveyors | Less work for people and keeps things clean |

Spindle power tells what size and type of parts the lathe can cut. Some machines, like the STA-Series and STC-Series, have spindle holes from 6" to 15". They can also hold parts up to 236 inches long. These lathes can cut big pipes and heavy pieces. Strong spindle power keeps the cutting speed steady, even with hard metals.

Bed size and swing show how big a part the lathe can turn. Swing over bed is the biggest round part the lathe can spin. Swing over carriage is needed for facing and boring jobs. Swing over gap lets the lathe work on even bigger parts, like flanges. Factories must pick the right size for their jobs to avoid problems.

Swing over bed is for normal turning jobs.

Swing over carriage is for facing and boring.

Swing over gap is for big discs or flanges.

Accessories depend on swing size for safety and good results.

Modern flat bed cnc lathes use smart control systems. These controls help with easy programming and checking the machine in real time. Operators can see tool wear and machine health, which helps make fewer mistakes. Good controls also let the lathe do more types of jobs.

Automation, like tool changers and loaders, helps the lathe work faster. One machine can do many jobs, so it saves time. Top brands give good help after you buy, like training and spare parts. This help keeps the machine running and saves money.

Tip: Always check if the maker has remote help and custom choices. These can help your factory work better for a long time.

Cnc flat bed lathes cost from $80,000 to over $300,000. Some higher-end brands cost more but offer better technology and higher accuracy. More affordable brands are suitable for smaller shops. The price typically covers setup, training, and maintenance, but the improved performance and speed make the investment worthwhile.

To pick the best flat bed CNC lathe, you need to know how it is different from a slant bed lathe. The table below shows how they are not the same in speed, accuracy, strength, price, and what jobs they do. This helps factories choose the right machine for their work.

Aspect | Flat Bed CNC Lathe | Slant Bed CNC Lathe |

|---|---|---|

Speed | Up to 2,500 RPM; prioritizes torque (1,500 Nm) for heavy material removal; cycle times 10–15% longer | Up to 4,500 RPM; faster cycle times by 15–20% for small parts |

Precision | Tolerances of 0.002mm; maintains precision under heavy load but chip buildup can affect repeatability | Tolerances of 0.002mm; better thermal stability due to coolant flow |

Durability & Maintenance | Requires cleaning every 250 hours due to chip accumulation; spindle bearings last 25,000 hours | Cleaning every 500 hours; linear guides last 15–20 years |

Initial Investment | $15,000–$40,000 depending on size and capacity | $5,000–$50,000 reflecting advanced features |

Operational Costs | Higher maintenance costs for chip cleanup; longevity offsets costs in heavy-duty use | Lower energy consumption; saves on maintenance |

ROI | 4–6 years; suited for long-term, heavy projects | 3–4 years; faster cost recovery in high-output settings |

Training Requirements | 10–20 hours; easier transition for operators familiar with manual lathes | 20–40 hours; more complex due to turret and CNC controls |

Ergonomics | Spacious bed (40-inch swing) but requires more reach | 30° slant bed reduces operator strain; easier tool access |

Space Requirements | Larger footprint (12 ft x 6 ft) | Smaller footprint (8 ft x 5 ft) |

Automation Integration | Less adaptable; favors manual setups | Seamless integration with bar feeders and robots |

Typical Applications | Heavy, large-diameter work (oil & gas, construction) | High-volume, medium-sized parts (aerospace, automotive) |

Note: Some flat bed CNC lathes can make parts with very tiny errors. This is important for things like airplanes and medical tools. They can also make smooth surfaces, so you do not need extra steps.

Modern flat bed CNC lathes have special features that help them stand out:

Automatic tool changers (ATCs) help change tools fast and keep the machine working.

Robotic systems can load and unload parts, which saves time and keeps work steady.

Smart CNC controllers, like the Siemens 808D Advanced, watch the machine and help fix problems right away.

Touchscreens make it easy to use and program the machine.

Live tooling lets the machine do more than one job, like milling, drilling, and tapping, without stopping to change setups.

These features help factories work faster, make fewer mistakes, and keep their products good even when the work is hard.

Picking the right cnc flat bed lathe means knowing what your factory makes. You need to think about the size and shape of your parts. Check what materials you will cut, like steel or plastic. Count how many parts you must make each day. Make sure the lathe can hold your biggest and smallest parts. It is important that the machine is accurate for every job. This matters most when parts must fit together well. Factories should also look at how many axes the lathe has. Spindle speed and tool choices are important too. These things help the machine do hard jobs.

Check how big and heavy your parts are

Think about what materials you will use

Decide how exact your parts must be

Count how many parts you need to make

Look at spindle power and tool options

Tip: Pick a flat bed cnc lathe from a good brand. Good brands give better help and their machines last longer.

Factories must plan where to put the lathe. Measure the floor to see if there is enough space. Make sure there is room to load and unload parts. Leave space for fixing and cleaning the machine. The lathe should fit in so parts move easily to the next step. Put the lathe where workers can reach it. Do not block other machines. A good setup keeps work safe and fast.

Measure the space you have

Plan how workers and parts will move

Leave space for cleaning and fixing

Do not put machines too close together

Money is important when picking a cnc flat bed lathe. Cheaper machines cost less but may not have many features. Expensive ones are faster and more exact. They can also do more jobs by themselves. Factories should think about more than just the price. Think about how much money the machine can save or make over time. You save money by making parts faster and wasting less. Some shops get more customers with better machines. Always ask sellers for real stories and proof.

Compare the price to how much you can save

Guess how much more you can earn

Look for ways to waste less and save time

Ask about training, help, and spare parts

Note: Talk to sellers and read real stories before you buy. Good help and care plans keep your machine working well.

Top CNC flat bed lathes are known for being very accurate and dependable. They also have smart features that help with hard jobs. Factories should do a few things before picking a machine:

Think about the size of your parts, what they are made of, and how many you need.

Make sure the machine is strong, makes parts right, and is simple to use.

Talk to trusted sellers to see the machine work or get good advice.

Planning ahead and getting help from experts makes it easier for factories to pick the right CNC flat bed lathe and do well for many years.

A flat bed CNC lathe handles large, heavy parts. It offers more torque and stability. A slant bed CNC lathe works faster with small parts. It fits better in tight spaces.

Most factories service their CNC flat bed lathes every 250 hours of use. Regular cleaning and oil checks help the machine last longer.

Yes. Many brands design their controls for easy learning. Operators usually need 10 to 20 hours of training before using the machine safely.

Factories in oil and gas, railways, marine, and heavy machinery use these lathes. They need strong machines for big, tough parts.

Operators should check the control panel for error codes. They can follow the manual’s steps or call technical support for help.