Views: 0 Author: Site Editor Publish Time: 2025-10-16 Origin: Site

Choosing between a vertical machining center and a horizontal machining center depends on what your shop needs. You should think about the parts you make. You should also think about how many you need. Think about your space and your budget too. Many shops pick vertical machining centers because they cost less. They also fit into smaller spaces. In 2017, U.S. shops bought about 7,800 vertical machines. They only bought 1,600 horizontal ones.

Vertical machines have an upright spindle. Horizontal machines have a spindle that faces sideways.

Here’s a quick look at how they compare:

Feature | Horizontal Machining Center (HMC) | Vertical Machining Center (VMC) |

|---|---|---|

Average Cost | $375,000 | $115,000 |

Space Requirement | Needs more space | Needs less space |

Production Capacity | Makes many parts fast | Makes fewer parts |

Think about what is most important for your shop as you read on.

Vertical machining centers cost less and fit in small areas. This makes them good for shops with less money and space.

Horizontal machining centers make many parts fast and well. They work best for hard or big parts.

Think about what you need to make. Vertical machines work better for small groups of parts. They are good if you need to change things often. Horizontal machines are better for making lots of parts.

Chips come off easier with horizontal machines. This helps tools last longer and keeps the area clean. It also means you stop working less often.

Use the checklist to look at your shop’s needs, money, and space. This will help you pick the best machining center for your work.

A vertical machining center is a cnc machine with a spindle that stands straight up. The workpiece sits on a flat table. Gravity helps hold it in place. You can watch the cutting easily. You can check your part and change things fast. Most shops use vertical machining centers for testing ideas, making tools, and small jobs. These machines cost less money. They also need less space than other machines.

Tip: If you want to make a few parts or change setups a lot, a vertical machining center is flexible and easy to use.

Here is a quick comparison of features:

Feature | Vertical Machining Center (VMC) |

|---|---|

Spindle Orientation | Vertical |

Workpiece Setup | Simple, gravity helps |

Chip Evacuation | Chips may pile up |

Visibility | Easy to monitor |

Applications | Prototyping, small batches |

Cost | Lower |

Footprint | Compact |

Productivity | Slower for multi-sided parts |

Horizontal machining centers have a spindle that lies sideways next to the worktable. You often need special holders for your workpiece. Chips fall off the part because gravity pulls them down. This keeps the area clean. You cannot see the cutting as well. These machines are good for making lots of parts and for hard jobs. Many factories use horizontal machining centers for heavy parts and for jobs that need work on many sides.

Feature | Horizontal Machining Center (HMC) |

|---|---|

Spindle Orientation | Horizontal |

Workpiece Setup | Needs complex fixtures |

Chip Evacuation | Chips fall away easily |

Visibility | Limited |

Applications | High-volume, complex parts |

Cost | Higher |

Footprint | Larger |

Productivity | Faster for multi-sided parts |

Pick a horizontal machine if you want to make many parts fast or need to work on many sides without moving the part.

A vertical machining center has a spindle that stands straight up. This lets you cut down into the workpiece. You can see the cutting area very well. This makes it easy to set up and watch your work. The table moves left and right, and forward and back. The spindle moves up and down. If you have used other cnc machines, this setup feels normal.

A horizontal machining center has a spindle that points sideways. It is level with the floor. Gravity helps chips fall away from the cutting area. These machines often use a rotary table. This lets you reach more sides of the part without moving it. You cannot see the cutting as well, but chips are managed better. The workspace stays cleaner.

Vertical machining centers cut straight down, so it is easy to see and set up.

Horizontal machining centers use gravity to move chips, which helps tools last longer.

In vertical machines, the spindle moves up and down. In horizontal machines, the spindle’s position helps remove chips well.

It is easy to load and check parts on a vertical machining center. You can set up jobs fast because you work from the top. This makes vertical machines good for testing ideas and making small batches. If you need to work on many sides, you may have to stop and move the part more than once.

Horizontal machining centers are better for big and heavy parts. The rotary table lets you reach many sides in one setup. This saves time and helps you make more parts. Setting up takes longer at first, but you do not have to move parts as much later. This makes horizontal machines great for making lots of parts and for hard jobs.

Feature | Vertical Machining Center | Horizontal Machining Center |

|---|---|---|

Worktable Area (mm) | 630 x 630 | 630 x 630 |

Maximum Workpiece Weight (KG) | 600 | 3000, 4000, 6000, 8000 |

Maximum Load Capacity of Work Table (T) | 0.6 | 3, 4, 6, 8 |

Note: Horizontal machining centers can hold much heavier parts than vertical ones. This is important if you work with big or heavy pieces.

Getting rid of chips is very important in machining. In a vertical machining center, chips can pile up around the tool and part. You may need a tool to move chips away, especially during long jobs. If chips build up, tools can wear out faster and parts may not be as accurate. You need to clean the table, rails, and tool holder after each shift to keep the machine working well.

A horizontal machining center uses gravity to move chips away from the cutting area. This keeps the workspace cleaner and stops chips from being cut again. Clean chips help tools stay cool and last longer. You spend less time cleaning, and the machine stays accurate longer. You still need to clean and oil the machine, but there are fewer chips to deal with in a horizontal machine.

In vertical machining centers, chips can build up and cause more wear and less accuracy.

Horizontal machining centers keep chips away, which helps keep parts precise and lowers cleaning time.

Both types need cleaning, but horizontal machines make it easier.

Tip: Good chip control helps you work faster and keeps your machine working well.

You should think about these differences when picking a machining center. Spindle direction, how you handle parts, and chip removal all matter. The right choice can help you make more parts, make better parts, and spend less time on cleaning.

A vertical machining center gives your shop many good things. You can set up jobs fast. This helps you save time when making small batches. You can change setups often and it is not hard. This makes vertical machining centers great for testing ideas and short jobs. You also spend less money because these machines cost less to buy and fix.

Here is a table that shows how vertical machining centers and horizontal machining centers compare for small-batch jobs:

Feature | Vertical Machining Centers (VMCs) | Horizontal Machining Centers (HMCs) |

|---|---|---|

Setup Time | Usually faster | Slower because it is more complex |

Best for | Small to medium runs | High-volume jobs |

Flexibility | High, good for many changes | Lower, best for big runs |

Cost | Costs less | Costs more |

Tip: If you want to save money and need to change jobs a lot, a vertical machining center is a good pick.

Horizontal machining centers help your shop make more parts. You can work on many sides of a part in one setup. This saves time and means you do not have to move the part much. Chips fall away better, so your area stays clean and tools last longer. These machines are good for making lots of parts and for heavy work.

Here are some real benefits of horizontal machining centers:

You can use the machine more, from about 30-40% up to 70-85% or more.

You lower the cost for each part by making more parts and using less labor.

You get better quality because you control the process and waste less.

Automation means you touch parts less and they are less likely to get damaged.

Both vertical machining centers and horizontal machining centers have some downsides. Vertical machining centers can have chips pile up, which can hurt the finish and wear out tools. It can be hard to use them for big or heavy parts. Horizontal machining centers cost more and are harder to set up. You need more skill and time to get started with them.

Here is a table that shows common limits:

Limitation | Vertical Machining Centers (VMCs) | Horizontal Machining Centers (HMCs) |

|---|---|---|

Chip Removal | Chips can pile up | Chips fall away but are harder to manage |

Workpiece Size | Best for smaller parts | Good for bigger, heavier parts |

Cost | Cheaper | Costs more to buy and keep up |

Setup Complexity | Easier to set up | Harder, needs more skill |

Note: Pick the machine that fits your shop, your budget, and the parts you make.

Pick a vertical machining center if you want easy setup and flexibility. These machines are good for shops that do many different jobs. They are also good if you change setups a lot. You can see your work well, so you can make changes fast. Vertical cnc machines fit in small spaces and cost less. This makes them a smart choice for many shops.

Many industries use vertical machining centers for important jobs. Here is a table that shows how different fields use these machines:

Industry | Applications |

|---|---|

Aerospace | Machining high-performance components like turbine blades, brackets, and structural airframe parts. |

Automotive | Essential for engine blocks, gearbox housings, cylinder heads, and suspension parts. |

Medical Devices | Production of orthopedic implants, dental prosthetics, and surgical tools requiring precision. |

You can use vertical cnc machines for testing ideas and making small batches. They are also good for parts that need to be very accurate. In aerospace, you might make complex parts like turbine blades. In automotive, you can make engine blocks and other car parts. Medical device makers use these machines for implants and tools.

Tip: Pick a vertical machining center if you want easy setup, clear visibility, and lower costs for smaller or varied jobs.

Pick horizontal machining centers if you need to make lots of parts fast. These machines are great for big or heavy parts. You can work on many sides of a part in one setup. This saves time and helps you make fewer mistakes. Horizontal machines keep chips away from the cutting area, so tools last longer.

Here is a table that shows how different industries use horizontal machining centers for complex and large jobs:

Industry | Part Complexity | Production Scale |

|---|---|---|

Aerospace | High precision, complex | Large batches |

Automotive | Moderate, larger parts | High volume |

Heavy Machinery | Low to moderate, large | High volume |

Medical Devices | High precision, complex | Moderate to low |

Tool and Die Making | Moderate, intricate | Moderate volume |

Use horizontal machines if you need to make many parts quickly or work with big pieces. These machines are best for high-volume jobs, like in car or heavy machinery factories. You also get better chip control, so your workspace stays clean and your tools last longer.

Note: Choose horizontal machining centers for jobs that need speed, efficiency, and the ability to handle complex or heavy parts.

You should think about how long setup takes for each machine. Vertical machining centers are quick to set up. You can reach the work area easily. You use simple fixtures with these machines. This helps you change jobs fast. Horizontal machining centers take longer to set up. You need more complex fixtures and careful alignment. The table below shows the difference:

Machining Center Type | Setup Time Characteristics |

|---|---|

Vertical Machining Centers (VMCs) | Generally faster due to easier access and simpler fixturing. |

Horizontal Machining Centers (HMCs) | Longer setup times due to complexity and precision requirements. |

If you switch jobs a lot, vertical cnc machines are more flexible. Horizontal machines are best for making many parts at once. They use pallet changers and tombstone fixtures. You can load new parts while the machine works. This means less waiting and more parts made.

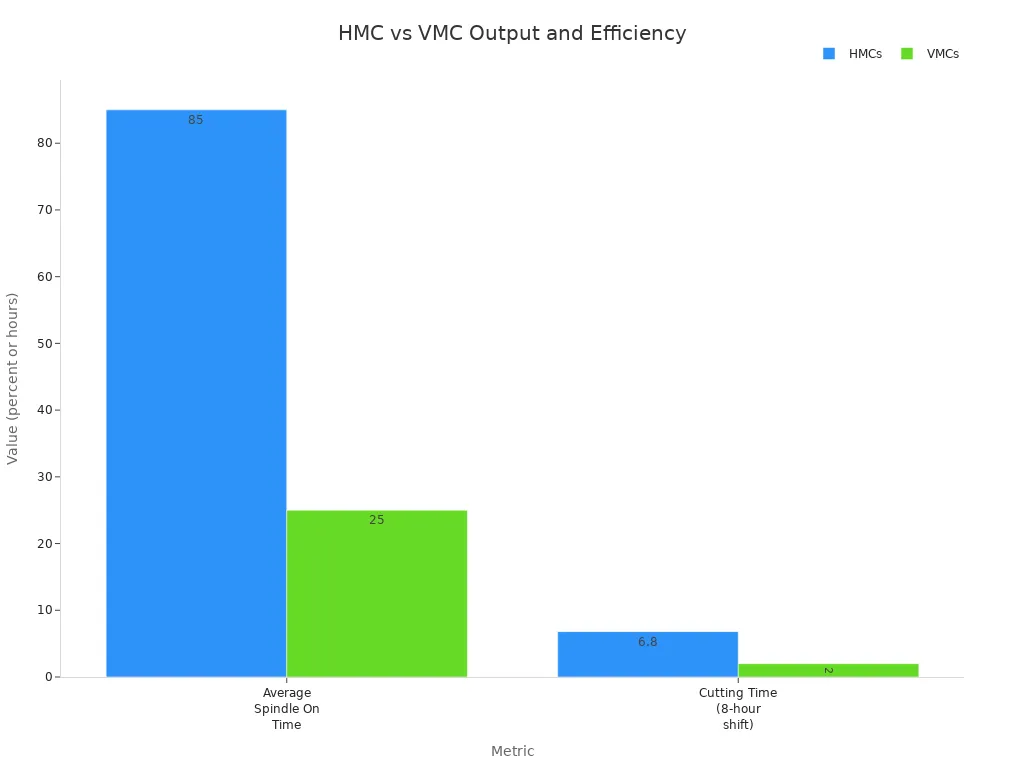

You want your machines to make lots of parts. Horizontal machining centers keep the spindle running longer. They can cut on more sides without stopping. This makes your output and efficiency better. Vertical machines must stop for each changeover. This lowers cutting time.

Metric | Horizontal Machining Centers (HMCs) | Vertical Machining Centers (VMCs) |

|---|---|---|

Average Spindle On Time | 85% | 25% |

Cutting Time (8-hour shift) | 6.8 hours | 2 hours |

Annual Productivity Advantage | 1,250 hours | N/A |

Revenue Advantage (per year) | $156,000 | N/A |

In real shops, horizontal machines can cut cycle times by up to 40%. Car factories and custom shops see faster work and higher output with horizontal machines. You finish more parts in less time.

You need to plan for the price and space of each machine. Vertical machining centers cost much less. You can buy one for about $15,000. Horizontal machines cost more, often around $375,000 or more. You also need more room for a horizontal machine. Vertical machines fit into smaller spaces. This helps if your shop is small.

Vertical machines are small and save money.

Horizontal machines need more space and cost more.

Think about your shop’s size, your budget, and how many jobs you have. If you have little space or want to spend less, vertical machines are a smart choice. If you need to make more parts and handle big jobs, a horizontal machine may be worth it.

You want to choose the best machining center for your shop. Use this checklist to compare vertical and horizontal machines. The table below shows what to check and how each machine matches your needs:

Checklist Item | Vertical Machining Center (VMC) | Horizontal Machining Center (HMC) |

|---|---|---|

Production Volume | Good for making fewer, very accurate parts | Best for making lots of parts with less stopping |

Part Complexity | Works well for simple parts or few sides | Better for tricky parts that need many sides done |

Facility Space | Needs less room and saves money | Costs more and needs a bigger area |

Budget Constraints | Cheaper to buy and run | Costs more but can make more parts faster |

Ask yourself these questions:

How many parts do you make each week?

Do your parts have many sides or are they tricky shapes?

How much space is in your shop?

What is your spending limit for new machines?

Tip: Write down your answers. This helps you see which machine is best for your shop.

You can find the right machine for your job by following these steps. Many experts suggest you do this:

Know what you need. Set a goal for how many parts you want each hour. Check how long it takes to switch jobs.

Match the machine to your work. Think about the material and how exact you need to be.

Balance how many parts you want with your budget. Think about how much you can spend.

Look at all the costs. Do not just look at the price tag.

Figure out how many parts you can make. Use cycle time and fixtures to help you.

Make sure the machine is safe and follows all rules.

You should also look at important things that affect your choice. This table explains what to think about:

Factor | Description |

|---|---|

Type of Operation and Material | Some machines work better with certain jobs and materials. |

Precision and Accuracy Requirements | Some jobs need very exact work. |

Machine Size and Work Envelope | The machine must fit your biggest part and your space. |

Spindle Speed and Power | Hard jobs and tough materials need more speed and power. |

Control System and Software Compatibility | The machine should work with your shop’s software. |

Tool Capacity and Changeover Time | More tools and quick changes help with different jobs. |

Machine Rigidity and Build Quality | A strong machine makes better and smoother parts. |

Production Volume and Duty Cycle | The machine must handle your work amount without problems. |

Think about how many different jobs and how many parts you make. This table can help you decide:

Machining Center Type | Production Volume | Job Diversity | Key Features |

|---|---|---|---|

Horizontal | High | Low | Removes material fast, good for hard shapes |

Vertical | Low | High | Easy to use, quick to set up, great for testing |

Note: If you make lots of complex parts, a horizontal machine may be best. If you need to do many different jobs, a vertical machine is often better.

Take time to think about what you need. Think about your money, your space, how hard your parts are, and your goals. This guide helps you pick the right machining center for your shop.

You now understand the big differences between vertical and horizontal machining centers. Vertical machines cost less money. They are quicker to set up. Horizontal machines work on more sides at the same time. They help you make more parts faster. Here is a simple comparison:

Feature | VMCs (Vertical) | HMCs (Horizontal) |

|---|---|---|

Cost | Cheaper | Costs more |

Setup Time | Quicker | Takes longer |

Efficiency | Good for small jobs | Best for lots of parts |

Choose the machine that fits your shop’s needs, space, and budget. Use the checklist to help you pick the best one for your work.

The biggest difference is how the spindle sits. A horizontal machining center has a spindle that goes sideways. This helps chips fall off and is good for making lots of parts.

Yes, you can use both machines for many jobs. They are used in aerospace, car making, and medical fields. Each machine is better for certain kinds of work.

Horizontal machining centers give better accuracy and are very steady. They hold heavy parts well and keep chips away from the cutting spot. This makes them good for high-precision parts.

Picking the right machine helps you make more parts. Horizontal machines can work on more parts at once. Vertical machines let you change jobs fast. Both help you finish work quicker.

Both machines can do precision machining. You need to pick the right one for your part’s size and shape. Good setup and care help you get the best results.